What Do You Need to Pack?

Advanced dosing systems adaptable to your specific product characteristics

Granule packaging involves products that may be fragile, vary in bulk density, or contain fine particles that can generate dust. These characteristics place higher demands on accurate dosing, stable feeding, and gentle handling to avoid breakage and weighing deviations.

Recommended equipment

Granule packaging involves products that may be fragile, vary in bulk density, or contain fine particles that can generate dust. These characteristics place higher demands on accurate dosing, stable feeding, and gentle handling to avoid breakage and weighing deviations.

Recommended equipment

Powder packaging involves materials that are highly prone to dust generation, moisture absorption, and caking. Many powders also have adhesive properties, which can lead to dosing inaccuracy and contamination of the sealing area. These challenges require controlled feeding, stable dosing, and effective dust management to maintain packaging consistency and durable sealing.

Recommended equipment

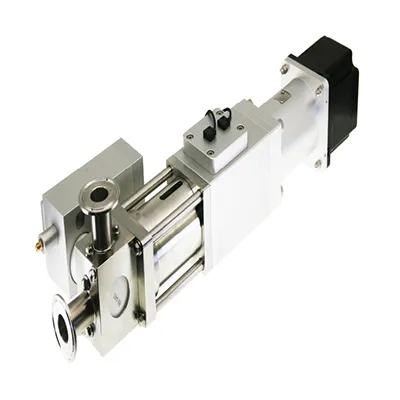

Unlike liquid, paste and sauce products have high viscosity and poor flow. Some formulations also contain solid particles, which makes discharge more difficult and increases the challenge of accurate dosing. Cleaning can also take longer if product residue builds up in the filling path. These applications require strong dosing stability, smooth product transfer, and equipment designs that support thorough sanitation.

Recommended equipment