What production speed can a rollstock flat pouch packaging line achieve?

What production speed can a rollstock flat pouch packaging line achieve?

The actual speed depends on the product and pouch size, but standard HFFS flat pouch packaging systems typically run between 60 and 120 pouches per minute. This range can cover most medium- to high-volume production requirements, and the exact output can be calculated based on your target capacity.

Is it easy to switch between different pouch sizes?

Is it easy to switch between different pouch sizes?

Yes. All format settings are stored as presets in the touchscreen of the rollstock flat pouch packaging machine. When changing sizes, operators simply select the right preset and most adjustments are completed automatically, keeping changeover time to a minimum.

How are yield and film waste controlled when using rollstock film?

How are yield and film waste controlled when using rollstock film?

High-precision photoelectric tracking keeps the cutting position accurate, while stable temperature control ensures consistent sealing. Together, these functions help maintain good pack quality and keep film waste low.

Are there any special requirements for the rollstock packaging film?

Are there any special requirements for the rollstock packaging film?

HFFS flat pouch packaging lines are compatible with common materials such as PE, CPP, and various laminated films. As long as the film type, thickness, and core size match the packaging equipment specifications, stable operation can be maintained.

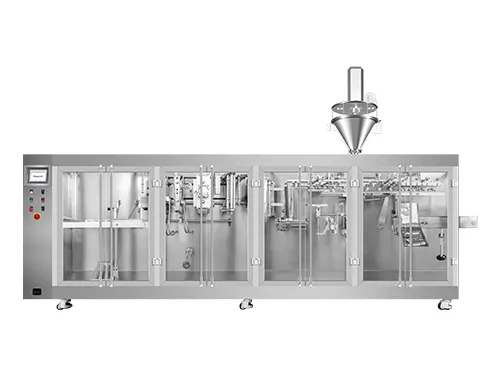

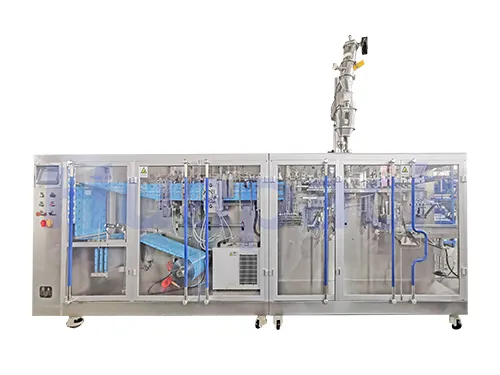

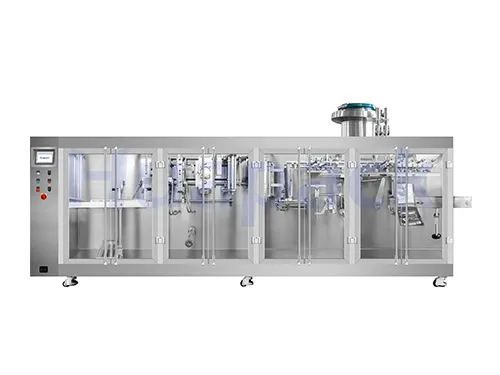

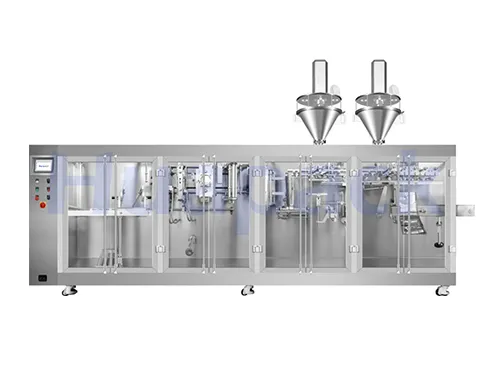

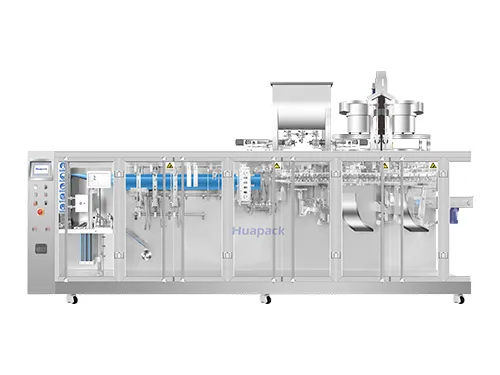

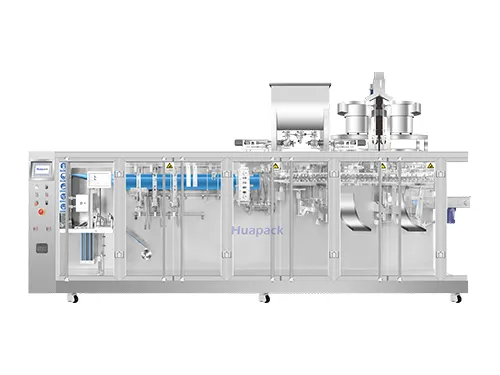

How much floor space do rollstock flat pouch packaging machines need?

How much floor space do rollstock flat pouch packaging machines need?

The layout of the rollstock flat pouch packaging machine is designed to be compact, which allows it to fit into most existing production areas without major changes. Thanks to their compact design, rollstock flat pouch packaging machines are suitable for factories where space is limited and where new equipment needs to be added without reorganizing the whole production line.