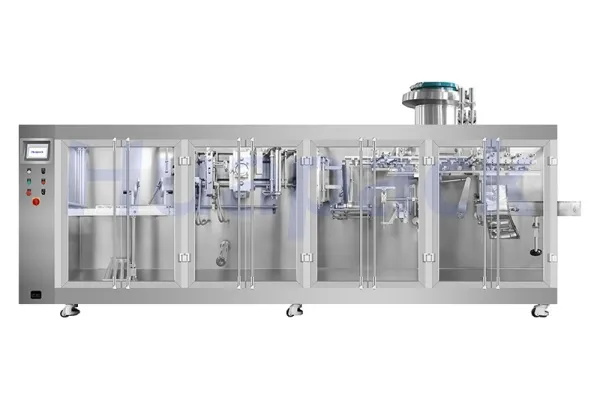

Spouted Pouch HFFS Packaging Machine, 1-Nozzle Filling

Horizontal form fill seal machine

From film forming and automatic spout feeding to accurate filling and heat sealing, this rollstock spouted pouch machine handles the whole process in one continuous flow. The single-nozzle layout keeps every station working in sync, helping maintain stable output and consistent pouch quality at speeds of up to 60 pouches per minute.

Applications

Ideal for products that need a strong, reliable seal, especially liquids, sauces, and oxygen-sensitive fillings. Suitable for products such as juice, yogurt, condiments, shower gel, and high-value chemical liquids, where keeping the pouch tight and leak-free is key to protecting product quality and shelf life.

Supported Pouch Types

Spouted pouches

Spouted pouches

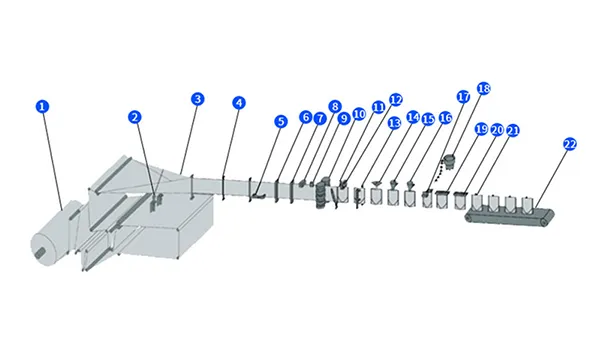

- Film unwinding

- Bottom hole punching

- Pouch forming

- Registration mark detection

- Bottom sealing

- First vertical sealing

- Second vertical sealing

- Easy-tear notch forming

- Hole punching

- Servo pouch pulling

- Cutting

- Pouch clamping

- Pouch opening

- Air blowing

- First filling

- Secondary filling

- Pouch expanding

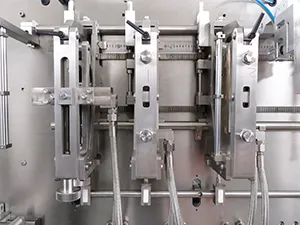

- Spout insertion

- Heat sealing

- Cooling sealing

- Finished pouch output

- Finished pouch conveying

| Rollstock spouted pouch parameters | | | | | |

| Pouch parameters | Min. pouch size (W × H) | 60x80mm | 75×85mm | 75x85mm | 70x85mm |

| Max. pouch size (W × H) | 130x180mm | 180×225mm | 240x225mm | 280x225mm | |

| Max. filling volume | 160ml | 400ml | 1000ml | 1500ml | |

| Packaging speed (pouches/min) | ≤60 | ≤60 | ≤50 | ≤50 | |

| Machine specifications | Machine dimensions (L × W × H) | 2850x920x1460mm | 4000mm×970mm×1450mm | 4500x970x1460mm | 4800x970x1460mm |

| Total machine weight | 1500kg | 1800kg | 2100kg | 2300kg | |

| Operating conditions | Air consumption | 200L/min | 300L/min | 300L/min | 300L/min |

| Main power | 3.5Kw | 5.5Kw | 5.5Kw | 5.5Kw | |

Zipper opening

Pouch hole punching

Sombrero hole (butterfly hole)

Sombrero hole (butterfly hole) Round hole

Round hole Special-shape punching

Special-shape punching Arc hole / Curved slot hole

Arc hole / Curved slot hole Euro hole

Euro hole

Coding options

Hot stamp coding

Hot stamp coding Inkjet printing

Inkjet printing Laser marking

Laser marking

Sealing patterns

Grid pattern

Grid pattern Dotted pattern

Dotted pattern Plain/flat pattern

Plain/flat pattern Vertical rib pattern

Vertical rib pattern

In 2024, a cosmetics company in Thailand chose our spouted pouch packaging solution for filling 30 g cosmetic products. The pouch packaging machine now runs steadily, delivering neat seals and uniform pouches that meet their daily production needs with reliable, repeatable results.

-

Factory overview

Factory overview -

Shipping & delivery

Shipping & delivery