Automatic Packaging Machines for Bag-in-Bag Package

Bag-in-bag packaging is a composite packaging format where one or multiple inner pillow bags are independently sealed inside an outer master pouch or secondary overwrap. This format allows different materials or products to be packed together while remaining physically separated. It supports functional separation, improved product protection, and flexible portion control. It is commonly used for products that require package more than one single-serve bags into a master bag, multi-component packaging, or combined contents within a single retail pack.

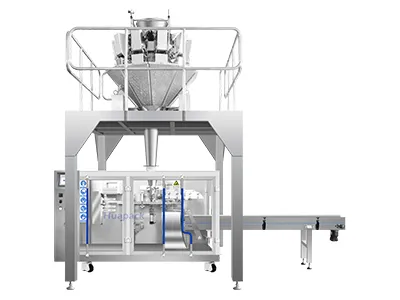

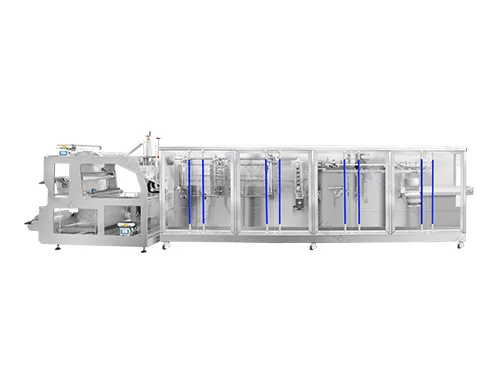

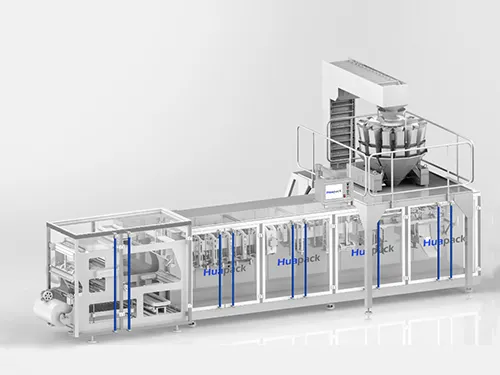

Recommended models