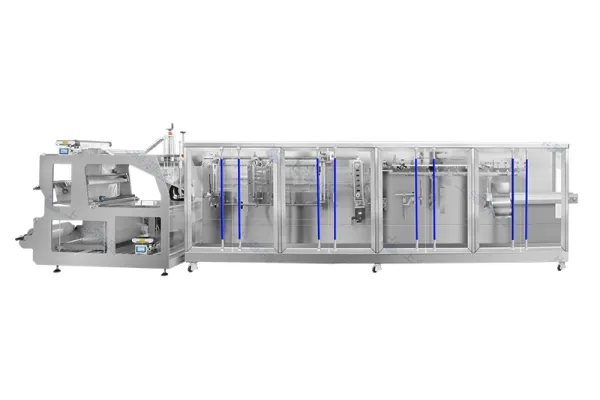

Stand-Up Pouch HFFS Packaging Machine, 1-Nozzle Filling

Horizontal form fill seal machine

These rollstock stand-up pouch packaging machines are used to produce pouches that can stand upright on their own, making them easy to display, store, and handle. Starting from roll film, the line forms stable bottom-gusset pouches and carries out filling and sealing in one continuous process, delivering clean, well-shaped stand-up packs with a consistent appearance and reliable sealing.

Applications

Supported Pouch Types

Stand-up pouches (doypack)/Zipper pouches

Stand-up pouches (doypack)/Zipper pouches Stand-up pouches (doypack)/Zipper pouches

Stand-up pouches (doypack)/Zipper pouches

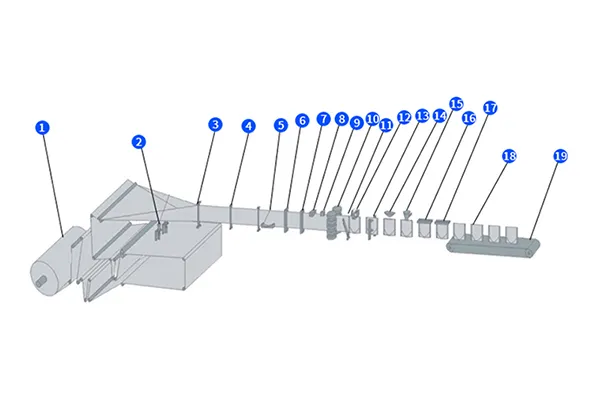

- Film unwinding

- Bottom hole punching

- Film forming

- Registration mark detection

- Bottom sealing

- First vertical sealing

- Second vertical sealing

- Easy-tear notch forming

- Hole punching

- Servo pouch pulling

- Cutting

- Pouch gripping

- Pouch opening

- Air blowing

- Filling

- Heat sealing

- Cooling sealing

- Finished pouch discharge

- Finished pouch conveying

- Equipped with a high precision forming unit that shapes flat rollstock film into a stable bottom gusset through controlled folding and pulling, creating the three-dimensional stand-up pouches that set these packaging machines apart from standard flat pouch packaging systems.

- An integrated continuous operation design, combined with servo drives and smart control, allows the line to run smoothly and steadily at high speed, reaching dynamic outputs of up to 60 pouches per minute.

| Performance features | Rollstock stand-up pouch/zipper pouch/spouted pouch | | | | |

| Pouch parameters | Min. pouch size | 80x120mm | 80x130mm | 90x150mm | 90x140mm |

| Max. pouch size | 130x200mm | 182x250mm | 240x350mm | 280x300mm | |

| Filling volume | 800ml | 1000ml | 2000ml | 3000ml | |

| Packaging speed | ≤60 | ≤60 | ≤60 | ≤50 | |

| Rollstock film thickness | 70-150μ | 70-150μ | 70-150μ | 70-150μ | |

| Max. rollstock film outer diameter | 500mm | 500mm | 500mm | 500mm | |

| Machine specifications | Rollstock film core inner diameter | 70-80mm | 70-80mm | 70-80mm | 70-80mm |

| Machine dimensions (L × W × H) | 5500x970x1450mm | 6500x970x1450mm | 7200x970x1460mm | 8000x1200x1800mm | |

| Machine weight | 1800kg | 2000kg | 2300kg | 3400kg | |

| Operating conditions | Air consumption | 300L/min | 300L/min | 400L/min | 650L/min |

| Main drive power | 8kw | 8kw | 9kw | 9.5kw |

Zipper opening

Pouch hole punching

Sombrero hole (butterfly hole)

Sombrero hole (butterfly hole) Round hole

Round hole Special-shape punching

Special-shape punching Arc hole / Curved slot hole

Arc hole / Curved slot hole Euro hole

Euro hole

Coding options

Hot stamp coding

Hot stamp coding Inkjet printing

Inkjet printing Laser marking

Laser marking

Sealing patterns

Grid pattern

Grid pattern Dotted pattern

Dotted pattern Plain/flat pattern

Plain/flat pattern Vertical rib pattern

Vertical rib pattern

A food company in Jiangsu focused on children’s nutrition, especially cheese products, purchased the 240S rollstock stand-up pouch machine in 2022. The brand has been growing quickly thanks to its own supply chain and clear market positioning. Since the stand up pouch packaging machine was installed, the company's production has been running smoothly, supporting their daily output and the consistent quality of their packaging.

-

Factory overview

Factory overview -

Shipping & delivery

Shipping & delivery