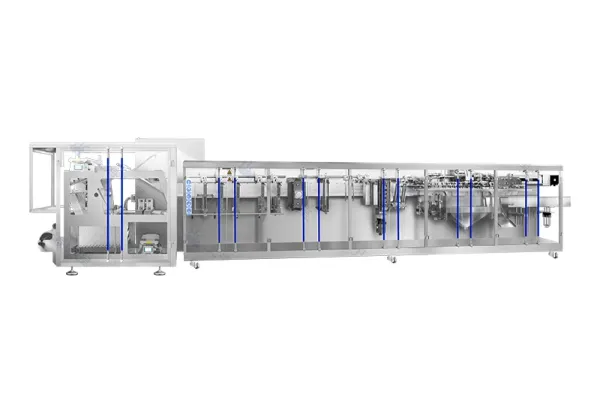

Spouted Stand-Up Pouch HFFS Packaging Machine, 2-Nozzle Filling

Horizontal form fill seal machine

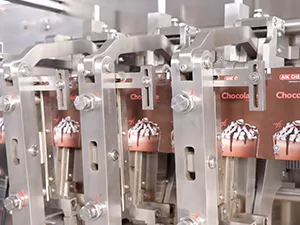

Rollstock spouted stand-up pouch packaging machines with dual-nozzle filling are suitable for high-efficiency production of high-quality ready-to-drink packs. These pouch packaging machines integrate a high-precision automatic spout feeding and pressing system, allowing each spout to be positioned and welded accurately and under clean conditions even at high speeds, fully synchronized with the filling and sealing process. These rollstock spouted stand-up pouch packaging machines are equipped with Siemens control systems on their key functions, which helps keep the whole operation stable and reduces the risk of unexpected stops, even during long and continuous production runs.

Maximum speed: 90 pouches per minute

Applications

Suitable for large-scale production of liquid and semi-liquid products such as juice, yogurt, jelly, and functional beverages, where stable filling, clean sealing, and high output are required.

Supported Pouch Types

Shaped pouches

Shaped pouches Spouted pouches

Spouted pouches

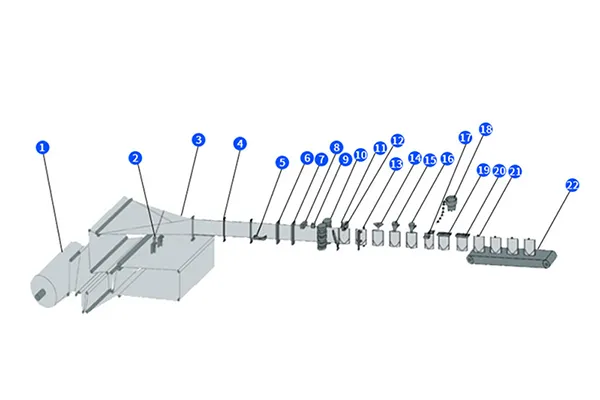

- Film unwinding

- Bottom hole punching

- Film forming

- Registration mark detection

- Bottom sealing

- First vertical sealing

- Second vertical sealing

- Easy-tear notch forming

- Hole punching

- Servo pouch pulling

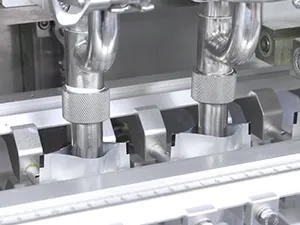

- Cutting

- Pouch clamping

- Pouch opening

- Air blowing

- First filling

- Secondary filling

- Pouch expanding

- Spout insertion

- Heat sealing

- Cooling sealing

- Finished pouch discharge

- Finished pouch conveying

| Performance features | Rollstock stand-up pouch parameters | | | | |

| Pouch parameters | Min. pouch size | 70x110mm | 90x125mm | 90x125mm | 90x125mm |

| Max. pouch size | 90x225mm | 120x250mm | 140x250mm | 165x250mm | |

| Filling volume | 300ml | 500ml | 500ml | 700ml | |

| Packaging speed | 60-120 | 60-120 | 60-100 | 60-90 | |

| Rollstock film thickness | 70-150μ | 70-150μ | 70-150μ | 70-150μ | |

| Max. rollstock film outer diameter | 500mm | 500mm | 500mm | 500mm | |

| Machine specifications | Rollstock film core inner diameter | 70-80mm | 70-80mm | 70-80mm | 70-80mm |

| Machine dimensions (L × W × H) | 6900x970x1450mm | 7200x970x1460mm | 8500x1100x1460mm | 9500x1100x1460mm | |

| Machine weight | 2100kg | 2500kg | 2500kg | 2500kg | |

| Operating conditions | Operating temperature | ﹣10℃-+50℃ | ﹣10℃-+50℃ | ﹣10℃-+50℃ | ﹣10℃-+50℃ |

| Operating humidity | Less than 85% | Less than 85% | Less than 85% | Less than 85% | |

| Power supply | AC380V, 50HZ | AC380V, 50HZ | AC380V, 50HZ | AC380V, 50HZ | |

| Air pressure | 0.6-0.7Mpa | 0.6-0.7Mpa | 0.6-0.7Mpa | 0.6-0.7Mpa | |

| Air consumption | 400L/min | 400L/min | 400L/min | 400L/min | |

| Main drive power | 8.8kw | 9.8kw | 12.8kw | 15.8kw |

Zipper opening

Pouch hole punching

Sombrero hole (butterfly hole)

Sombrero hole (butterfly hole) Round hole

Round hole Special-shape punching

Special-shape punching Arc hole / Curved slot hole

Arc hole / Curved slot hole Euro hole

Euro hole

Coding options

Hot stamp coding

Hot stamp coding Inkjet printing

Inkjet printing Laser marking

Laser marking

Sealing patterns

Grid pattern

Grid pattern Dotted pattern

Dotted pattern Plain/flat pattern

Plain/flat pattern Vertical rib pattern

Vertical rib pattern

For their ketchup products, a food company supplying the Yemen and Saudi markets chose a rollstock stand-up pouch machine with straight spout to pack ketchup in small pouches with a capacity of 50–70 g. The pouch packaging machine our client purchased was ideal for the products they wanted to handle, and it has been running smoothly, delivering consistent fills and neat spout sealing in daily production.

-

Factory overview

Factory overview -

Shipping & delivery

Shipping & delivery