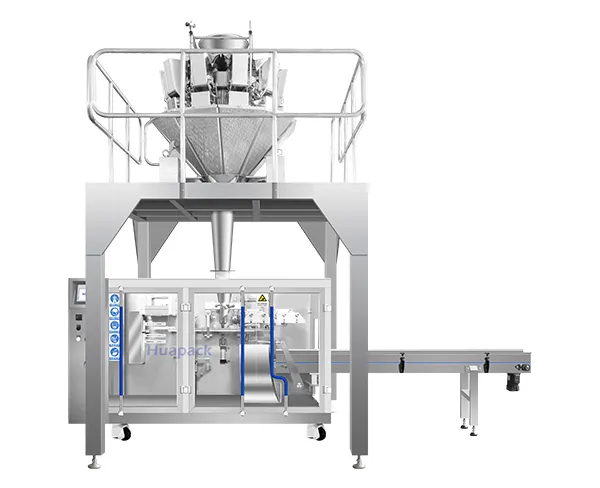

Premade Pouch Packaging Machine (1-Nozzle Filling, 5 Stations)

Compact pouch filling and sealing system for space-limited production with high flexibility of bag styles

Designed for small and medium production lines, these premade pouch packaging machines use a five-station structure with one filling nozzle. Compared with traditional eight-station packaging machines, the reduced number of stations keeps the main steps of pouch opening, filling, and sealing, while making the overall packaging machine more compact and helping save space on the production floor. They can run common ready-made pouch formats such as stand-up, zipper, pouches, and are suitable for packaging powders, granules, liquids, and viscous products.

Applicable Pouch Types

Our flexible packaging machines are widely applicable to a variety of pouch types, including Stand-up Pouch, Flat Pouch, Zipper Pouch, Spouted Pouch, Gusset Pouch, and more.

Supported Pouch Types

Flat pouches

Flat pouches Flat pouches

Flat pouches Stand-up pouches (doypack)/Zipper pouches

Stand-up pouches (doypack)/Zipper pouches Stand-up pouches (doypack)/Zipper pouches

Stand-up pouches (doypack)/Zipper pouches Shaped pouches

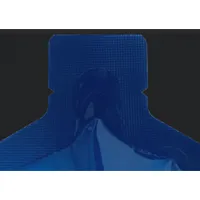

Shaped pouches Spouted pouches

Spouted pouches

Applicable Products

Liquids, powders, granules, and viscous products.

- Compact layout

The five-station layout requires less floor space than traditional eight-station machines, which is ideal for factories that have limited space and supports a more efficient workshop layout. - Wide pouch format support

Suitable for different pouch types, including three-side seal, four-side seal, stand-up pouches, zipper pouches, and spouted pouches. - Flexible dosing options

Can be equipped with different filling systems such as auger fillers, cup fillers, and liquid pumps, enabling accurate dosing of powders, granules, liquids, and viscous products. - Easy operation

A touch-screen interface with clear parameter settings and recipe storage, so different products can be set up quickly and production parameters adjusted easily. - Hygienic and durable structure

The parts that come in contact with the products are made of stainless steel and designed to meet food hygiene requirements.

| Model | | |

| Packaging parameters | Min. pouch size (W × H) | 70×130mm |

| Max. pouch size (W × H) | 240×350mm | |

| Max. filling volume | 2000ml | |

| Packing speed (pouches/min) | ≤40 | |

| Equipment specifications | Machine dimensions (L × W × H) | 1960mm×1100mm×1250mm |

| Total machine weight | 800kg | |

| Operating conditions | Ambient temperature | -10℃-+55℃ |

| Relative humidity (non-condensing) | <85% | |

| Power supply | AC380V, 50Hz | |

| Working air pressure | 0.6Mpa | |

| Air consumption | 300L/min | |

| Main motor power | 2.3Kw | |

Zipper opening

Pouch hole punching

Sombrero hole (butterfly hole)

Sombrero hole (butterfly hole) Round hole

Round hole Special-shape punching

Special-shape punching Arc hole / Curved slot hole

Arc hole / Curved slot hole Euro hole

Euro hole

Coding options

Hot stamp coding

Hot stamp coding Inkjet printing

Inkjet printing Laser marking

Laser marking

Sealing patterns

Grid pattern

Grid pattern Dotted pattern

Dotted pattern Plain/flat pattern

Plain/flat pattern Vertical rib pattern

Vertical rib pattern

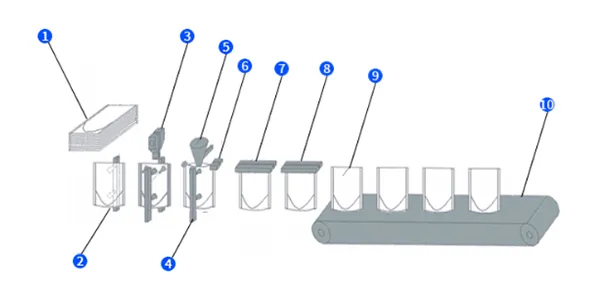

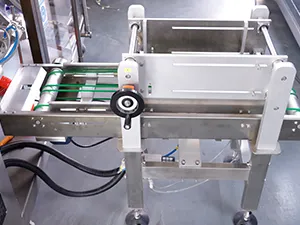

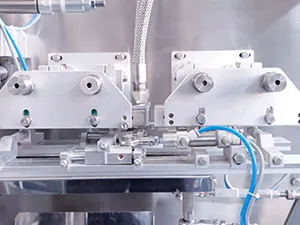

Pouch pick-up unit

Pouch pick-up unit Filling unit

Filling unit Heat sealing unit

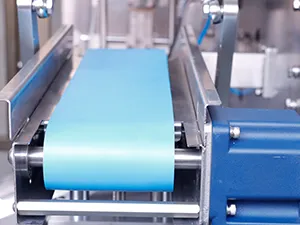

Heat sealing unit Finished pouch discharge unit

Finished pouch discharge unit

-

Factory overview

Factory overview -

Shipping & delivery

Shipping & delivery