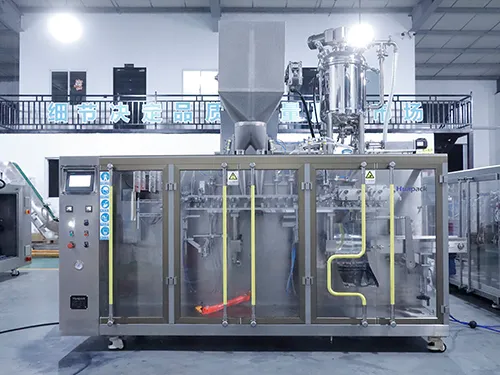

Premade pouch packaging machines with dual-nozzle filling are designed for higher output requirements by running two synchronized lanes at the same time. This configuration runs two lanes at the same time, so pouch pick-up, opening, filling, and sealing are carried out in parallel. It is a good option for production lines that need higher output and stable, continuous operation.

Can a premade pouch packaging machine with two filling nozzles help improve production efficiency?

Can a premade pouch packaging machine with two filling nozzles help improve production efficiency?

With two filling nozzles working at the same time, two pouches are processed in each cycle. Pouch pick-up, opening, filling, and sealing run in sync, which increases output and makes this configuration suitable for production lines that handle large orders and need to run continuously.

How does a two-nozzle premade pouch packaging machine maintain stable operation in daily production?

How does a two-nozzle premade pouch packaging machine maintain stable operation in daily production?

Premade pouch packaging machines with two filling nozzles are controlled by a PLC system, which allows smooth and synchronized operation at high running speed. Thanks to stable control logic it's possible to reduce unexpected stops and support continuous, reliable production with a low fault rate.

If a factory currently uses manual case packing, can cartoning and palletizing equipment be added to the pouch packaging machine later?

If a factory currently uses manual case packing, can cartoning and palletizing equipment be added to the pouch packaging machine later?

Premade pouch packaging machines with two filling nozzles can be connected to downstream equipment such as case packers and palletizers, to allow the packing process to move from manual case packing to a more automated line. Depending on production needs, cartoning and palletizing systems can be added step by step, helping reduce labor requirements and improve overall line efficiency.

If order volume is growing and single-nozzle equipment cannot meet capacity, can a two-nozzle packaging machine solve this?

If order volume is growing and single-nozzle equipment cannot meet capacity, can a two-nozzle packaging machine solve this?

Two filling nozzles work in parallel, so two pouches are processed in each cycle instead of one. Compared with single-nozzle operation, efficiency can increase by more than 80%, and the combined theoretical output can reach up to 100 pouches per minute, which helps packaging lines handle higher volumes and solve capacity limitations more effectively.