400DG

Premade Pouch Packaging Machine, 2-Nozzle Filling

These 2-nozzle automatic premade pouch packaging machines are designed to handle larger pouch formats, including stand-up pouches and flat pouches with capacities of up to 1000 ml. Wider bags and higher filling volumes can be processed smoothly, while the dual-nozzle, dual-lane configuration allows two pouches to be filled at the same time, keeping a good packing speed and stable pouch handling for medium to large-scale production.

Applications

Supported Pouch Types

Flat pouches

Flat pouches Flat pouches

Flat pouches Stand-up pouches (doypack)/Zipper pouches

Stand-up pouches (doypack)/Zipper pouches Stand-up pouches (doypack)/Zipper pouches

Stand-up pouches (doypack)/Zipper pouches

Applicable Products

Liquids, powders, granules, and viscous products.

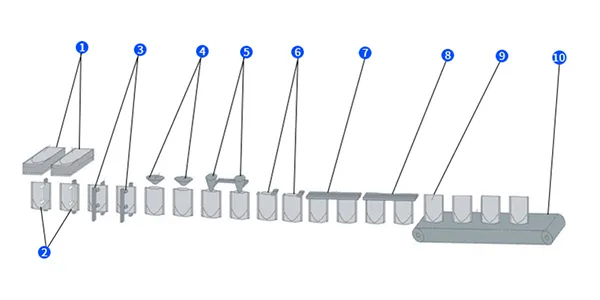

Process Flow

Features

Larger premade pouches can be handled smoothly, making this solution suitable for medium to large pack sizes and products with higher filling volumes. - Two premade pouches are processed in parallel, from picking and opening to filling and sealing. When both lanes run in parallel, more pouches can be packed in the same amount of time, which makes it much easier to keep up with large orders and tight production schedules.

- By changing the feeding system, the same packaging line can work with different product types, including liquids, powders, and granules, allowing one setup to cover multiple applications.

- A wide variety of pouch styles can be handled smoothly, such as three-side seal, four-side seal, stand-up pouches, shaped pouches, and zipper pouches, giving more flexibility for different packaging designs.

- Equipped with a PLC-based control system to coordinate all main movements, keeping the packaging operation stable and ensuring continuous, well-synchronized production.

- The line can be connected with auxiliary equipment such as inkjet printers, checkweighers, cartoners, case packers, labeling machines, and palletizers, to make it easy to build a complete and automatic packaging line.

Specifications

| Model | 400DG | |

| Packaging parameters | Min. pouch size (W × H) | 70x130mm |

| Max. pouch size (W × H) | 190x300mm | |

| Max. filling volume | 1000ml | |

| Packing speed (pouches/min) | ≤90 | |

| Equipment specifications | Machine dimensions (L × W × H) | 4400mmx2600mmx1400mm |

| Total machine weight | 3000kg | |

| Operating conditions | Ambient temperature | -10℃-+55℃ |

| Relative humidity (non-condensing) | <85% | |

| Power supply | AC380V, 50Hz | |

| Working air pressure | 0.6Mpa | |

| Air consumption | 560L/min | |

| Main motor power | 7.5Kw | |

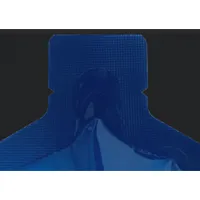

Optional Functions

Zipper opening

Pouch hole punching

Sombrero hole (butterfly hole)

Sombrero hole (butterfly hole) Round hole

Round hole Special-shape punching

Special-shape punching Arc hole / Curved slot hole

Arc hole / Curved slot hole Euro hole

Euro hole

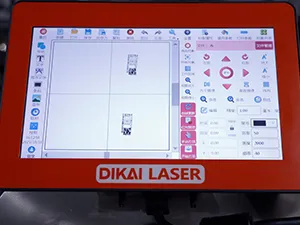

Coding options

Hot stamp coding

Hot stamp coding Inkjet printing

Inkjet printing Laser marking

Laser marking

Sealing patterns

Grid pattern

Grid pattern Dotted pattern

Dotted pattern Plain/flat pattern

Plain/flat pattern Vertical rib pattern

Vertical rib pattern

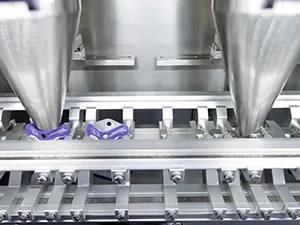

Details

Control panel

Control panel Electrical system

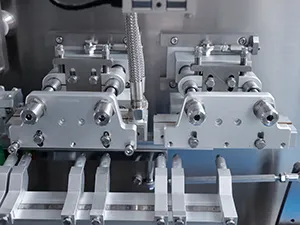

Electrical system Filling section

Filling section Workstation details

Workstation details

Customer Case Studies

-

Factory overview

Factory overview -

Shipping & delivery

Shipping & delivery

As a specialized manufacturer of flexible packaging machinery, Huapack focuses on providing automated flexible packaging lines that seamlessly integrate dosing, filling, and sealing (capping). Constructed with robust industrial-grade stainless steel, the premade pouch and rollstock pouch packaging machines we supply are proven to ensure stability during 7x24 hour high-intensity production. With a footprint in over 50 countries, we are committed to being your long-term partner for reliable flexible packaging machines with responsive after-sales support.