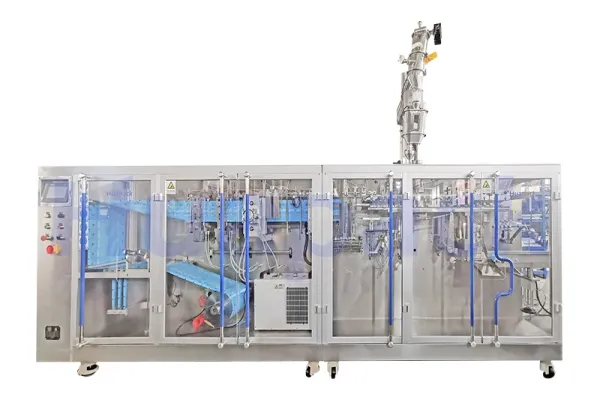

Flat Pouch HFFS Packaging Machine, 2-Nozzle Filling

Horizontal form fill seal machine

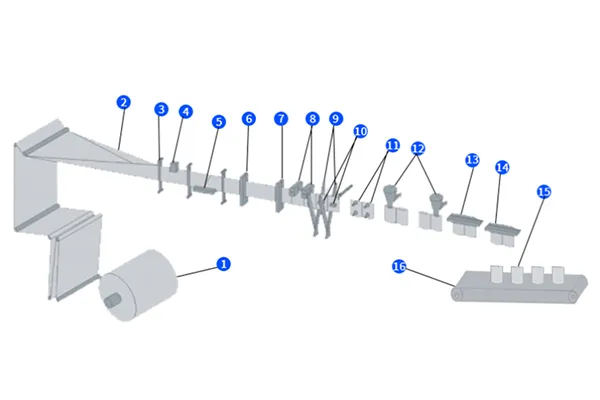

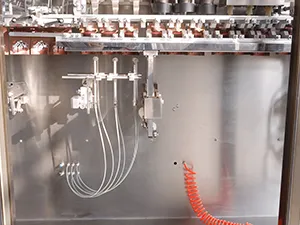

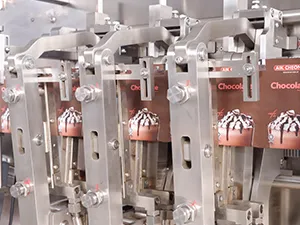

These rollstock flat pouch packaging machines with 2-nozzle filling integrate two complete packaging lanes into a single HFFS system. Both lanes share the same drive and control platform but work in parallel, so pouch forming and dosing are carried out simultaneously under the same horizontal sealing unit. This double lane (2-nozzles) design allows output to be much higher than that of single-nozzle models, which is suitable for large-scale production of the same product where high speed and stable, continuous operation are required.

Applications

Supported Pouch Types

Flat pouches

Flat pouches Flat pouches

Flat pouches

| Performance features | Rollstock flat pouch parameters | | | | |

| Pouch parameters | Min. pouch size | 60x90mm | 70x130mm | 70x130mm | 70x130mm |

| Max. pouch size | 90x180mm | 120x300mm | 140x300mm | 160x300mm | |

| Filling volume | 100ml | 150ml | 200ml | 400ml | |

| Packaging speed | ≤100 | ≤120 | ≤100 | ≤90 | |

| Rollstock film thickness | 70-150u | 70-150u | 70-150u | 70-150u | |

| Max. rollstock film outer diameter | 500mm | 500mm | 500mm | 500mm | |

| Machine specifications | Rollstock film core inner diameter | 70-80mm | 70-80mm | 70-80mm | 70-80mm |

| Machine dimensions (L × W × H) | 3500x970x1450 | 5200x970x1460 | 6500x970x1460 | 7200x970x1460 | |

| Machine weight | 1800kg | 2100kg | 2200kg | 2300kg | |

| Operating conditions | Operating temperature | ﹣10℃-+50℃ | ﹣10℃-+50℃ | ﹣10℃-+50℃ | ﹣10℃-+50℃ |

| Operating humidity | Less than 85% | Less than 85% | Less than 85% | Less than 85% | |

| Power supply | AC380V, 50HZ | AC380V, 50HZ | AC380V, 50HZ | AC380V, 50HZ | |

| Air pressure | 0.6Mpa | 0.6Mpa | 0.6Mpa | 0.6Mpa | |

| Air consumption | 200L/min | 300L/min | 300L/min | 300L/min | |

| Main drive power | 5.5kw | 5.5kw | 5.5kw | 5.5kw |

Zipper opening

Pouch hole punching

Sombrero hole (butterfly hole)

Sombrero hole (butterfly hole) Round hole

Round hole Special-shape punching

Special-shape punching Arc hole / Curved slot hole

Arc hole / Curved slot hole Euro hole

Euro hole

Coding options

Hot stamp coding

Hot stamp coding Inkjet printing

Inkjet printing Laser marking

Laser marking

Sealing patterns

Grid pattern

Grid pattern Dotted pattern

Dotted pattern Plain/flat pattern

Plain/flat pattern Vertical rib pattern

Vertical rib pattern

A food manufacturer in Russia purchased the 240ND rollstock flat pouch packaging machine to pack 20 g seasoning sachets. Since the machine was installed, it has been running steadily in daily production, and the customer has given positive feedback, with no major after-sales issues reported.

-

Factory overview

Factory overview -

Shipping & delivery

Shipping & delivery