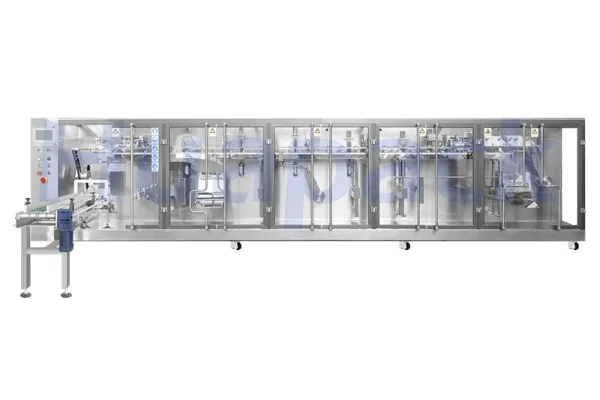

Premade Pouch Packaging Machine, 1-Nozzle Filling

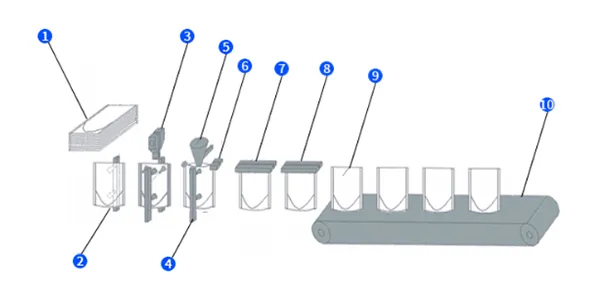

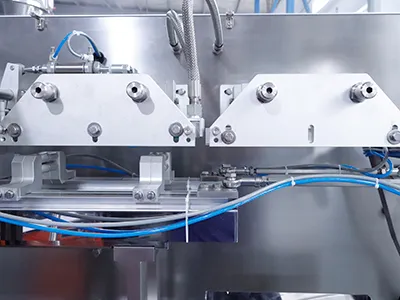

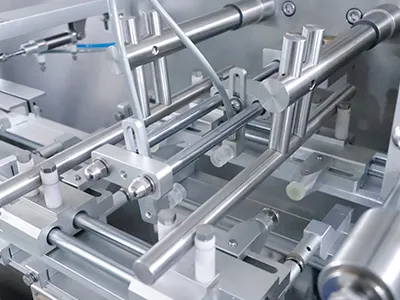

Operating at a stable speed of around 40 pouches per minute, these horizontal premade pouch packaging machines are designed for large fill volumes of up to 4000 ml and built with a reinforced structure and high-performance servo drives for continuous, heavy-duty production. The larger hopper and wider filling range reduce the need for frequent refilling, helping the line run more smoothly. These premade pouch filling systems are equipped with a vacuum and nitrogen flushing system to remove air efficiently from high-volume pouches, and the reinforced heat-sealing unit creates firm, reliable seals.

Applications

Suitable for packing large-size pouches in industries such as household and personal care, pharmaceuticals, and pet food.

Supported Pouch Types

Flat pouches

Flat pouches Flat pouches

Flat pouches

| Model | 330NG | |

| Pouch parameters | Min. pouch size (W × H) | 110×150mm |

| Max. pouch size (W × H) | 330×500mm | |

| Max. filling volume | 4000ml | |

| Packing speed (pouches/min) | ≤40 | |

| Equipment specifications | Machine dimensions (L × W × H)) | 3475mm×1215mm×1600mm |

| Total machine weight | 1800kg | |

| Operating conditions | Ambient temperature | -10℃-+55℃ |

| Relative humidity (non-condensing) | <85% | |

| Power supply | AC380V, 50Hz | |

| Working air pressure | 0.6Mpa | |

| Air consumption | 400L/min | |

| Main motor power | 5.5Kw | |

Zipper opening

Pouch hole punching

Sombrero hole (butterfly hole)

Sombrero hole (butterfly hole) Round hole

Round hole Special-shape punching

Special-shape punching Arc hole / Curved slot hole

Arc hole / Curved slot hole Euro hole

Euro hole

Coding options

Hot stamp coding

Hot stamp coding Inkjet printing

Inkjet printing Laser marking

Laser marking

Sealing patterns

Grid pattern

Grid pattern Dotted pattern

Dotted pattern Plain/flat pattern

Plain/flat pattern Vertical rib pattern

Vertical rib pattern

In 2024, a pharmaceutical company based in Guangzhou purchased our 330NG premade pouch packaging machine to improve their packaging process. Since commissioning, the packaging equipment has been running smoothly, and the customer has reported stable operation with no after-sales issues.

-

Factory overview

Factory overview -

Shipping & delivery

Shipping & delivery