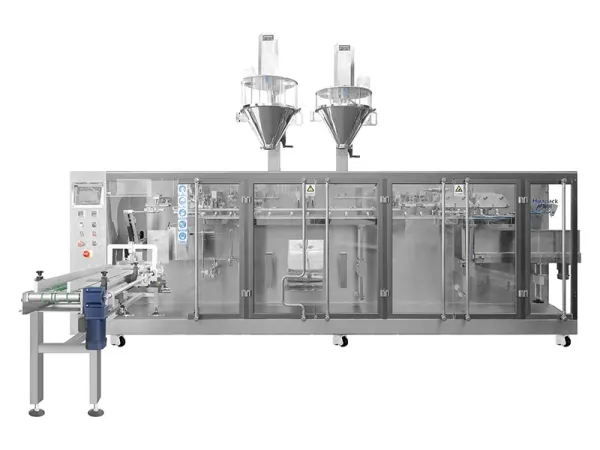

Premade Pouch Packaging Machine with Automatic Pouch Feeder, 1-Nozzle Filling

These premade pouch packaging machines are designed to work with various types of pouch formats, such as stand-up pouches, pouch-in-pouch packs, eight-side-seal designs, with a filling capacity of up to 3000ml. They are equipped with an automatic pouch feeder with a hand-like separation system that can pick and separate even laminated pouches that tend to stick together, keeping feeding smooth and reliable. Thanks to their stable output of about 45 pouches per minute, these filling and sealing system fit well for products such as chocolate, high-grade tea, specialty nuts, and cosmetics. The components that touch the product are made of high-quality stainless steel, which makes them easy to clean, resistant to corrosion, and suitable for meeting the hygiene requirements of food and pharmaceutical production.

Applications

Supported Pouch Types

Stand-up pouches (doypack)/Zipper pouches

Stand-up pouches (doypack)/Zipper pouches Stand-up pouches (doypack)/Zipper pouches

Stand-up pouches (doypack)/Zipper pouches

| Model | 280G-F |

| Pouch size range | (Min.) 120×140mm (Max.) 280×400mm |

| Max. filling volume | 3000ml |

| Packaging speed | ≤45 |

| Machine dimensions (L × W × H) | 3200×2600×1500mm |

| Machine weight | 1500kg |

| Installed power | 5.5kw |

| Air consumption | 450L/min |

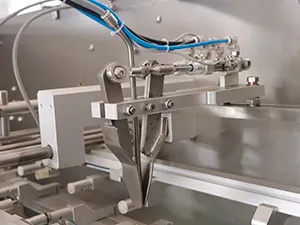

Zipper opening

Pouch hole punching

Sombrero hole (butterfly hole)

Sombrero hole (butterfly hole) Round hole

Round hole Special-shape punching

Special-shape punching Arc hole / Curved slot hole

Arc hole / Curved slot hole Euro hole

Euro hole

Coding options

Hot stamp coding

Hot stamp coding Inkjet printing

Inkjet printing Laser marking

Laser marking

Sealing patterns

Grid pattern

Grid pattern Dotted pattern

Dotted pattern Plain/flat pattern

Plain/flat pattern Vertical rib pattern

Vertical rib pattern

In 2025, a food producer based in Hohhot added our 3000ml 1-nozzle fillinf premade pouch packaging machine to its line for packing 282 g cheese sticks in flat pouches. The pouch packaging equipment was chosen to ensure stable filling, clean sealing, and a neat final presentation for this high-volume retail product.

-

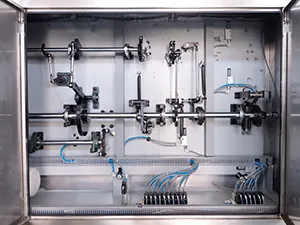

Factory overview

Factory overview -

Shipping & delivery

Shipping & delivery