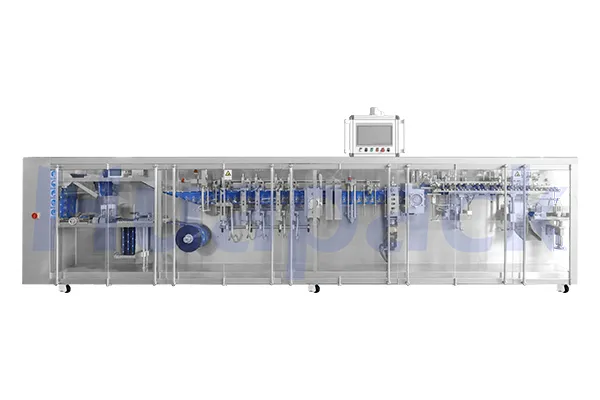

Rollstock Shaped Pouch Packaging Machine, 2-Nozzle Filling

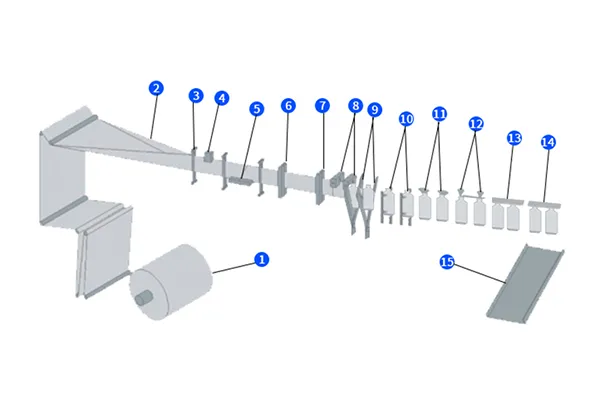

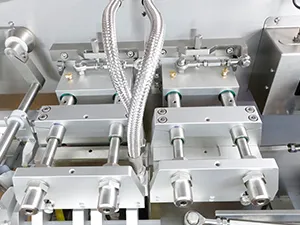

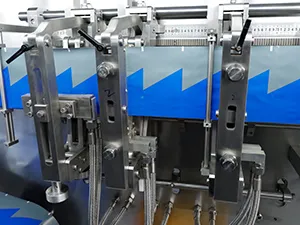

The rollstock shaped pouch packaging machines with 2 nozzles combine the material cost advantages of roll film with the productivity of a dual-lane pouch filling machine. Packaging speed can be flexibly adjusted within a range of 60 to 140 pouches per minute, allowing production to scale according to product type and capacity requirements. They are designed for fast changeover between shaped flat pouches and stand-up pouches, enabling multiple pouch formats to be produced on a single platform. This versatility supports manufacturers seeking both packaging diversity and long-term cost efficiency. Stable pouch forming, consistent sealing, and controlled operation make the system suitable for continuous production across varied applications.

Applications

Supported Pouch Types

Flat pouches

Flat pouches Flat pouches

Flat pouches Shaped pouches

Shaped pouches Stand-up pouches with straight spout

Stand-up pouches with straight spout

| Models | | | | |

| Pouch parameters | Min. pouch size (W × H) | 63mm×110mm | 75mm×110mm | 85mm×130mm |

| Max. pouch size (W × H) | 90mm×180mm | 90mm×180mm | 100mm×240mm | |

| Max. filling volume (stand-up pouch) | 180ml | 200ml | 350ml | |

| Packaging speed | ≤100 packs/min | ≤100 packs/min | ≤120 packs/min | |

| Equipment specifications | Dimensions (L × W × H) | 5200mm×1100mm×1500mm | 5000mmx1100mmx1500mm | 5500mmx1100mmx1500mm |

| Operating conditions | Net weight | 2500kg | 2500kg | 3000kg |

| Air consumption | 400L/min | 400L/min | 400L/min | |

| Motor power | 8.8Kw | 9Kw | 9Kw | |

Zipper opening

Pouch hole punching

Sombrero hole (butterfly hole)

Sombrero hole (butterfly hole) Round hole

Round hole Special-shape punching

Special-shape punching Arc hole / Curved slot hole

Arc hole / Curved slot hole Euro hole

Euro hole

Coding options

Hot stamp coding

Hot stamp coding Inkjet printing

Inkjet printing Laser marking

Laser marking

Sealing patterns

Grid pattern

Grid pattern Dotted pattern

Dotted pattern Plain/flat pattern

Plain/flat pattern Vertical rib pattern

Vertical rib pattern

-

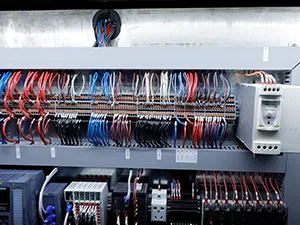

Factory overview

Factory overview -

Shipping & delivery

Shipping & delivery