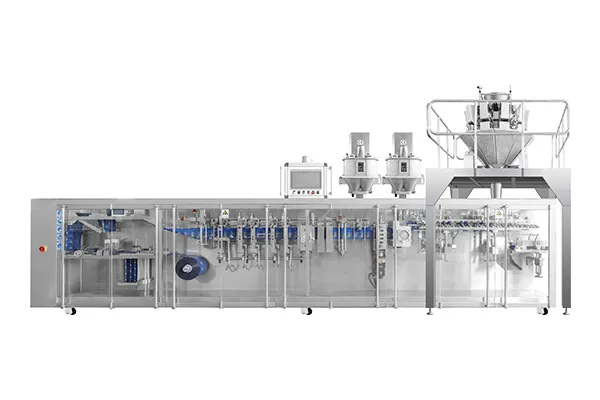

Rollstock Shaped Pouch Packaging Machine, 1-Nozzle Filling

Designed with a single-nozzle filling system, the rollstock shaped pouch packaging machines balance cost efficiency, simplified operation, and flexible pouch forming. By forming pouches directly from roll film, the system reduces material costs while maintaining stable pouch shaping and sealing quality. These pouch packaging machines are capable of producing a wide range of shaped flat pouches and stand-up pouches, making them suitable for manufacturers handling multiple SKUs or frequent product changeovers. Its simple and reliable design makes it a strong choice for medium to high batch production that requires both flexibility and stable performance.

Applications

Supported Pouch Types

Shaped pouches

Shaped pouches

| Models | | | | |

| Pouch parameters | Min. pouch size (W × H) | 60mm×130mm | 70mm×130mm | 75mm×85mm |

| Max. pouch size (W × H) | 180mm×180mm | 180mm×225mm | 240mm×225mm | |

| Max. filling volume (stand-up pouch) | 500ml | 400ml | 1000ml | |

| Packaging speed | ≤60 packs/min | ≤60 packs/min | ≤50 packs/min | |

| Equipment specifications | Dimensions (L × W × H) | 3980mm×1100mm×1500mm | 3500mm×970mm×1450mm | 4500mm×970mm×1460mm |

| Net weight | 2000kg | 1800kg | 2100kg | |

| Operating conditions | Air consumption | 400L/min | 200L/min | 300L/min |

| Motor power | 8kw | 5kw | 5.5kw | |

Zipper opening

Pouch hole punching

Sombrero hole (butterfly hole)

Sombrero hole (butterfly hole) Round hole

Round hole Special-shape punching

Special-shape punching Arc hole / Curved slot hole

Arc hole / Curved slot hole Euro hole

Euro hole

Coding options

Hot stamp coding

Hot stamp coding Inkjet printing

Inkjet printing Laser marking

Laser marking

Sealing patterns

Grid pattern

Grid pattern Dotted pattern

Dotted pattern Plain/flat pattern

Plain/flat pattern Vertical rib pattern

Vertical rib pattern

-

Factory overview

Factory overview -

Shipping & delivery

Shipping & delivery