Servo Driven Premade Pouch Packaging Machine, 4-Nozzle Filling

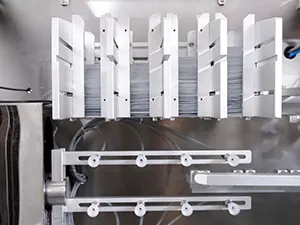

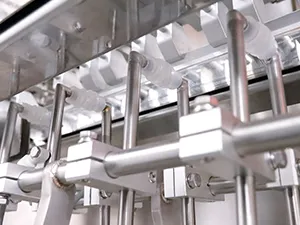

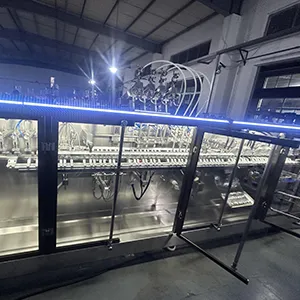

The servo driven premade pouch packaging machine is built with four independent servo drive systems, allowing all four stations to operate in fully synchronized parallel motion. This configuration enables a production capacity of up to 200 pouches per minute, making this pouch packing machine well suited for large-scale, high-standard manufacturing environments. Servo-driven control ensures precise pouch handling, stable filling, and consistent sealing across all lanes, even at high speeds. The system is designed for manufacturers that require both output efficiency and process accuracy, especially when scaling production without compromising on packaging quality.

Applications

Supported Pouch Types

Flat pouches

Flat pouches Flat pouches

Flat pouches Shaped pouches

Shaped pouches Spouted pouches

Spouted pouches

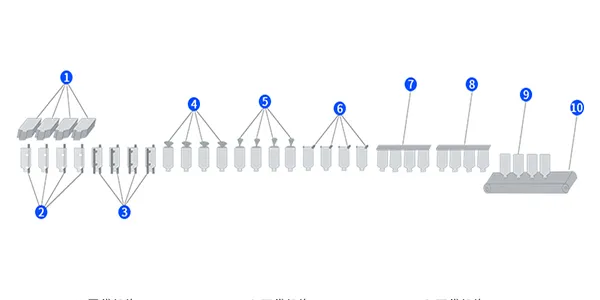

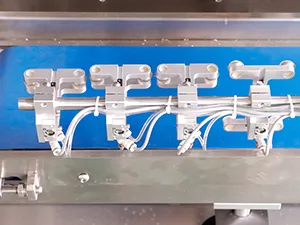

- Each station is driven by its own servo motor, based on European motion control technology. With each station controlled separately, all main movements, such as pouch picking, opening, filling, and sealing, stay in sync, so the packaging line can work smoothly for long hours without losing stability or accuracy.

- A wide range of premade pouch styles can be handled, including three-side seal, four-side seal, stand-up pouches, shaped pouches, and zipper pouches. By selecting different filling systems, the same line can work with liquids, powders, granules, and pastes, covering applications in food, personal care, and health products.

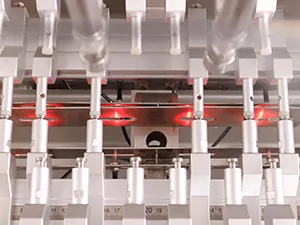

- An intelligent pouch detection system checks whether each pouch is properly opened before filling. If a pouch doesn’t open properly, the packaging system simply skips filling it, so product isn’t wasted and there’s no mess inside the machine.

- When four lanes (4 nozzles) work at the same time, many more pouches can be packed in a day compared to a standard two-lane line. In real production, this kind of setup can easily go beyond 100,000 pouches per day without pushing the machine to its limits.

| Model | 400QG | |

| Packaging parameters | Min. pouch size (W × H) | 65×130mm |

| Max. pouch size (W × H) | 90×250mm | |

| Max. filling volume | 100ml | |

| Packing speed (pouches/min) | ≤180包/min | |

| Equipment specifications | Machine dimensions (L × W × H) | 4250mm×1100mm×1500mm |

| Total machine weight | 2500kg | |

| Operating conditions | Ambient temperature | -10℃-+55℃ |

| Relative humidity (non-condensing) | <85% | |

| Power supply | AC380V, 50Hz | |

| Working air pressure | 0.6Mpa | |

| Air consumption | 600L/min | |

| Main motor power | 9.5Kw | |

Zipper opening

Pouch hole punching

Sombrero hole (butterfly hole)

Sombrero hole (butterfly hole) Round hole

Round hole Special-shape punching

Special-shape punching Arc hole / Curved slot hole

Arc hole / Curved slot hole Euro hole

Euro hole

Coding options

Hot stamp coding

Hot stamp coding Inkjet printing

Inkjet printing Laser marking

Laser marking

Sealing patterns

Grid pattern

Grid pattern Dotted pattern

Dotted pattern Plain/flat pattern

Plain/flat pattern Vertical rib pattern

Vertical rib pattern

A biotechnology company in Shandong, backed by the research of Academician Ling Pei, widely known in China for his work in hyaluronic acid, focuses on the development and production of health supplements and cosmetic products across the full value chain. In 2024, the company purchased a four-nozzle premade pouch packaging line from us for shaped pouches, and it has been running smoothly in their production, supporting stable and reliable output since its installation.

-

Factory overview

Factory overview -

Shipping & delivery

Shipping & delivery