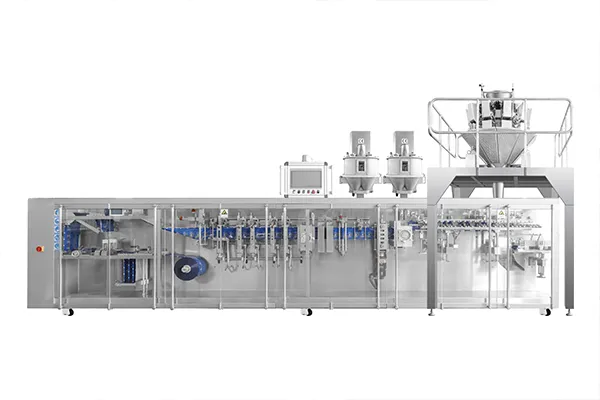

Servo Driven Rollstock Stand-Up Pouch Packaging Machine, 4-Nozzle Filling

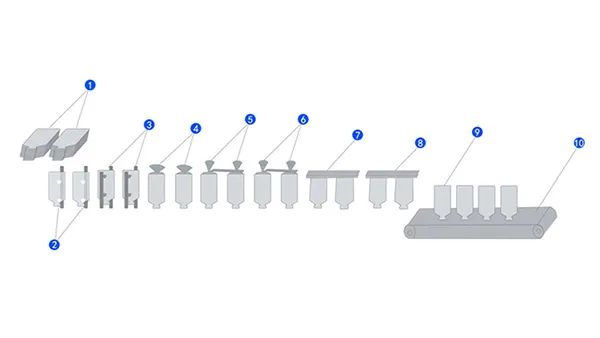

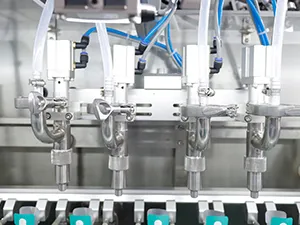

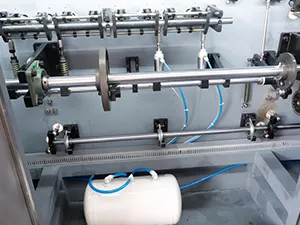

The servo driven rollstock stand-up pouch packaging machine combines four independent servo drives with rollstock pouch forming, allowing four shaped stand-up pouches to be produced at the same time. The system is built for high-output production while maintaining stable pouch forming and sealing quality. Roll film processing allows more flexibility in pouch design and helps control packaging material costs. The pouch handling machine is ideal for large-volume production where efficiency and pouch appearance are both important.

Applications

Supported Pouch Types

Shaped pouches

Shaped pouches

| Model | 400SQY | |

| Pouch parameters | Min. pouch size (W × H) | 60 mm ×130mm |

| Max. pouch size (W × H) | 90 mm ×200mm | |

| Max. filling volume (stand-up pouch) | 100ml | |

| Packaging speed | ≤200 packs/min | |

| Equipment specifications | Dimensions (L × W × H) | 3475mm×1215mm×1600mm |

| Net weight | 1800kg | |

| Operating conditions | Operating temperature | -10℃ to +55℃ |

| Relative humidity (non-condensing) | ≤ 85% | |

| Power supply | AC380V, 50Hz | |

| Operating air pressure | 0.6Mpa | |

| Air consumption | 400L/min | |

| Motor power | 4.5Kw | |

Zipper opening

Pouch hole punching

Sombrero hole (butterfly hole)

Sombrero hole (butterfly hole) Round hole

Round hole Special-shape punching

Special-shape punching Arc hole / Curved slot hole

Arc hole / Curved slot hole Euro hole

Euro hole

Coding options

Hot stamp coding

Hot stamp coding Inkjet printing

Inkjet printing Laser marking

Laser marking

Sealing patterns

Grid pattern

Grid pattern Dotted pattern

Dotted pattern Plain/flat pattern

Plain/flat pattern Vertical rib pattern

Vertical rib pattern

Guizhou Biotechnology is a health supplement manufacturer. In 2024, they purchased this rollstock shaped pouch packaging machine from us and has been our long-term customer, having introduced multiple packaging machine models over time for different production needs.

-

Factory overview

Factory overview -

Shipping & delivery

Shipping & delivery