Servo Driven Rollstock Zipper Pouch Packaging Machine, 2-Nozzle Filling

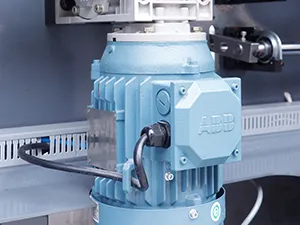

The servo driven rollstock zipper pouch packaging machines use a dual-lane configuration to form pouches directly from roll film while installing zippers inline with high precision. This enables fast, automated production of zipper pouches with consistent sealing quality and clean pouch appearance.

Servo-driven control ensures stable pouch forming, accurate zipper positioning, and smooth operation at higher speeds. The system is designed for manufacturers that require re-closable packaging combined with efficient output and flexible pouch formats. They are widely used for premium snacks, frozen foods, coffee and tea, dry pet food, and daily chemical products, where both functionality and shelf presentation are important.

Applications

Supported Pouch Types

Stand-up pouches (doypack)/Zipper pouches

Stand-up pouches (doypack)/Zipper pouches Stand-up pouches (doypack)/Zipper pouches

Stand-up pouches (doypack)/Zipper pouches

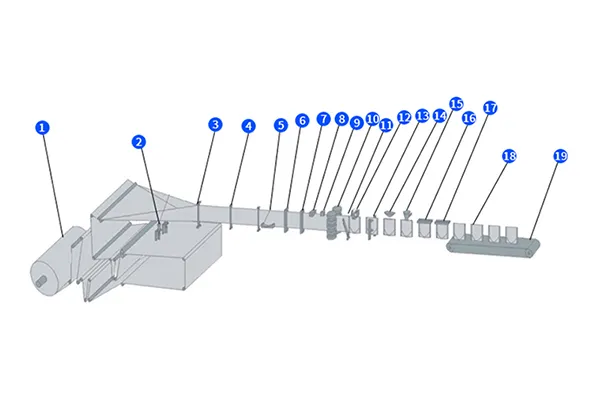

- Film unwinding

- Bottom hole punching

- Film forming

- Registration mark detection

- Bottom sealing

- First vertical sealing

- Second vertical sealing

- Easy-tear notch forming

- Hole punching

- Servo pouch pulling

- Cutting

- Pouch gripping

- Pouch opening

- Air blowing

- Filling

- Heat sealing

- Cooling sealing

- Finished pouch discharge

- Finished pouch conveying

| Performance features | Rollstock flat pouch parameters | | | | |

| Pouch parameters | Min. pouch size | 70x110mm | 90x125mm | 90x125mm | 90x125mm |

| Max. pouch size | 90x225mm | 120x250mm | 140x250mm | 165x250mm | |

| Filling volume | 300ml | 500ml | 500ml | 700ml | |

| Packaging speed | 60-120 | 60-120 | 60-100 | 60-90 | |

| Rollstock film thickness | 70-150μ | 70-150μ | 70-150μ | 70-150μ | |

| Max. rollstock film outer diameter | 500mm | 500mm | 500mm | 500mm | |

| Machine specifications | Rollstock film core inner diameter | 70-80mm | 70-80mm | 70-80mm | 70-80mm |

| Machine dimensions (L × W × H) | 6900x970x1450 | 7200x970x1460 | 8500x1100x1460 | 9500x1100x1460 | |

| Machine weight | 2100kg | 2500kg | 2500kg | 2500kg | |

| Operating conditions | Operating temperature | ﹣10℃-+50℃ | ﹣10℃-+50℃ | ﹣10℃-+50℃ | ﹣10℃-+50℃ |

| Operating humidity | Less than 85% | Less than 85% | Less than 85% | Less than 85% | |

| Power supply | AC380V, 50HZ | AC380V, 50HZ | AC380V, 50HZ | AC380V, 50HZ | |

| Air pressure | 0.6-0.7Mpa | 0.6-0.7Mpa | 0.6-0.7Mpa | 0.6-0.7Mpa | |

| Air consumption | 400L/min | 400L/min | 400L/min | 400L/min | |

| Main drive power | 8.8kw | 9.8kw | 12.8kw | 15.8kw |

Zipper opening

Pouch hole punching

Sombrero hole (butterfly hole)

Sombrero hole (butterfly hole) Round hole

Round hole Special-shape punching

Special-shape punching Arc hole / Curved slot hole

Arc hole / Curved slot hole Euro hole

Euro hole

Coding options

Hot stamp coding

Hot stamp coding Inkjet printing

Inkjet printing Laser marking

Laser marking

Sealing patterns

Grid pattern

Grid pattern Dotted pattern

Dotted pattern Plain/flat pattern

Plain/flat pattern Vertical rib pattern

Vertical rib pattern

In 2024, a Russian company that specializes in pet food purchased the 240SZ rollstock zipper stand-up pouch packaging machine to pack their products. The pouch packaging machine has been running smoothly since then, with no after-sales issues, and the customer has been very satisfied with its performance.

-

Factory overview

Factory overview -

Shipping & delivery

Shipping & delivery