240SDZ/280SDZ/330SDZ

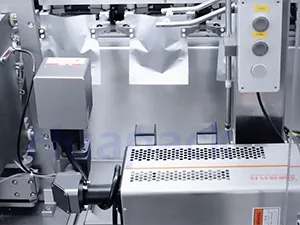

Servo Driven Flexible Pouch Packaging Machine, Continuous Motion

The servo driven flexible pouch packaging machine is built on a continuous, one-direction motion principle. It offers true production flexibility as different pouch sizes and product specifications can be handled through program adjustment, without complex mechanical changeovers. This allows fast response to changing production needs. The pouch handling machine operates in a continuous motion cycle. All working units move in the same direction throughout the process, eliminating traditional reciprocating movements. This supports smoother operation, higher stability, and improved efficiency at speed.

Applications

Supported Pouch Types

Flat pouches

Flat pouches Flat pouches

Flat pouches Stand-up pouches (doypack)/Zipper pouches

Stand-up pouches (doypack)/Zipper pouches Stand-up pouches (doypack)/Zipper pouches

Stand-up pouches (doypack)/Zipper pouches Shaped pouches

Shaped pouches Stand-up pouches with straight spout

Stand-up pouches with straight spout

Features

- Full servo drive system

Each motion axis is powered by an independent servo motor for precise and coordinated control. - Modular functional design

Filling systems can be quickly changed based on product characteristics, supporting different materials and applications. - Smart HMI interface

Operators select the required recipe, and the machine automatically adjusts all parameters. Changeover time is reduced from hours to just minutes.

Specifications

| Model | Pouch size range (W × H) | Max filling volume | Packaging speed | dimensions (L × W × H) | Net Weight |

| | (min)100×180 (max)180×250 | 1000ml | ≤60 packs/min | 3700mm×1560mm×1950mm | 2000kg |

| | (min)120×240 (max)240×320 | 2000ml | ≤45 packs/min | 3800mm×1650mm×1950mm | 2300kg |

| | (min)140×280 (max)280×350 | 2500ml | ≤40 packs/min | 4200mm×1800mm×1950mm | 3200kg |

| | (min)100×180 (max)180×250 | 1000ml | ≤60 packs/min | 3700mm×1560mm×1950mm | 2000kg |

| | (min)120×240 (max)240×320 | 2000ml | ≤45 packs/min | 3800mm×1650mm×1950mm | 2300kg |

| | (min)140×280 (max)280×350 | 2500ml | ≤40 packs/min | 4200mm×1800mm×1950mm | 3200kg |

Optional Functions

Zipper opening

Pouch hole punching

Sombrero hole (butterfly hole)

Sombrero hole (butterfly hole) Round hole

Round hole Special-shape punching

Special-shape punching Arc hole / Curved slot hole

Arc hole / Curved slot hole Euro hole

Euro hole

Coding options

Hot stamp coding

Hot stamp coding Inkjet printing

Inkjet printing Laser marking

Laser marking

Sealing patterns

Grid pattern

Grid pattern Dotted pattern

Dotted pattern Plain/flat pattern

Plain/flat pattern Vertical rib pattern

Vertical rib pattern

Details

Customer Case Studies

-

Factory overview

Factory overview -

Shipping & delivery

Shipping & delivery

As a specialized manufacturer of flexible packaging machinery, Huapack focuses on providing automated flexible packaging lines that seamlessly integrate dosing, filling, and sealing (capping). Constructed with robust industrial-grade stainless steel, the premade pouch and rollstock pouch packaging machines we supply are proven to ensure stability during 7x24 hour high-intensity production. With a footprint in over 50 countries, we are committed to being your long-term partner for reliable flexible packaging machines with responsive after-sales support.